![]()

Members

ABiogás (Brazilian Biogas Association)

Website: https://abiogas.org.br/en/

The Brazilian Biogas Association (ABiogás) was founded in 2013 by the union of people and companies that collaboratively seek to increase the deployment of biogas in Brazil.

Acting as a channel of dialogue with civil society, the Federal and State Governments, the autarchies and the bodies responsible for the Brazilian energy planning. ABiogás aims to transform the electric, fuel and thermal energy generated by biogas into widely available energy commodities. used, with a 10% share in the Brazilian energy market.

Currently, Brazil has the greatest energy potential in the world: 84.6 billion Nm³ / year between sanitation (7%), sugar-energy waste (48%) and agro-industrial waste (45%). This potential has the capacity to supply almost 40% of the national demand for electricity or replace 70% of the Brazilian diesel consumption.

ABiogás has associated companies that represent all sectors of the production, use and improvement chain in the biogas segment. With responsibility in acting with the competent bodies and a commitment to the disclosure of relevant information, ABiogás, its associates and partners always aim to achieve the best and most transformative results for Brazilian society.

AB Energy SpA (Italy)

Website: https://www.gruppoab.com/en/

AB is today the global benchmark for cogeneration, biogas and biomethane sectors. AB designs, manufactures, installs and services the best performing solutions on the world market.

The entire production process takes place in our own factories in Orzinuovi (BS – Italy), that represent the world’s most important industrial centre in this field, on a site comprising approximately 40,000 square metres of interconnected buildings.

Reliability and performance are guaranteed by a dedicated service, with more than 250 specialist technicians operating worldwide. Over 1,250 cogeneration plants have been installed to date, with a total nominal electrical power of more than 1,600 MW.

In the past few years the company’s production capacity has quadrupled, with the number of employees increasing to 900. AB now has direct subsidiaries in Europe, Russia, North America and South America.

ACT Commodities

Website:https://www.actcommodities.com/

ACT Commodities is one of the world’s leading providers of environmental and energy market solutions. Founded in 2009 as one of the first companies to pursue this market, we are now one of the most prominent specialists and offer more than 40 products in four core markets: emissions, renewable energy, energy efficiency, and fuels. This includes widespread activity in the biogas, biomethane, and feedstock markets.

ACT Commodities operates from offices in Amsterdam, Paris, Shanghai, Singapore, and New York. From these locations we serve over 5,000 customers worldwide, helping companies achieve environmental compliance, meet voluntary environmental goals, and trade (bio)fuels and feedstocks.

ACT Commodities has accumulated an unrivaled knowledge in legislation, products, markets, and logistics which allows us to give our clients the most up-to-date information.

Adani Total Energies

Website: https://www.adani.com/

Adani Group is a diversified organisation in India comprising 7 publicly traded companies. It has created a world class transport and utility infrastructure portfolio that has a pan-India presence. Adani Group is headquartered in Ahmedabad, in the state of Gujarat, India. Over the years, Adani Group has positioned itself to be the market leader in its transport logistics and energy utility portfolio businesses focusing on large scale infrastructure development in India with O & M practices benchmarked to global standards. With four IG rated businesses, it is the only Infrastructure Investment Grade issuer in India.

Adani owes its success and leadership position to its core philosophy of ‘Nation Building’ driven by ‘Growth with Goodness’ – a guiding principle for sustainable growth. Adani is committed to increase its ESG footprint by realigning its businesses with emphasis on climate protection and increasing community outreach through its CSR programme based on the principles of sustainability, diversity and shared values.

Agrilux

Agrivert Ltd

Website: https://www.agrivert.co.uk/

Agrivert delivers proven and innovative solutions for your organic waste management challenges through a full range of services, from design concept to full commercial infrastructure and operational management. Agrivert specialises in delivering biogas anaerobic digestion facilities and infrastructure in the UK and internationally with a pedigree hallmarked by a demonstrated ability to significantly outperform the industry norms for energy generation, uptime and profitability, maximising efficiency and minimising downtime.

Air Liquide

Website: https://www.airliquide.com/

A world leader in gases, technologies and services for Industry and Health, Air Liquide is present in 80 countries with approximately 66,000 employees and serves more than 3.6 million customers and patients. Oxygen, nitrogen and hydrogen are essential small molecules for life, matter and energy. They embody Air Liquide’s scientific territory and have been at the core of the company’s activities since its creation in 1902.

Air Liquide’s ambition is to be a leader in its industry, deliver long term performance and contribute to sustainability. The company’s customer-centric transformation strategy aims at profitable growth over the long term. It relies on operational excellence, selective investments, open innovation and a network organization implemented by the Group worldwide. Through the commitment and inventiveness of its people, Air Liquide leverages energy and environment transition, changes in healthcare and digitization, and delivers greater value to all its stakeholders.

Air Liquide’s revenue amounted to 21 billion euros in 2018 and its solutions that protect life and the environment represented more than 40% of sales. Air Liquide is listed on the Euronext Paris stock exchange (compartment A) and belongs to the CAC 40, EURO STOXX 50 and FTSE4Good indexes.

Anaergia

Website: https://www.anaergia.com/about-us

Anaergia is the world leader in solving waste problems by recovering renewable energy, water, and fertilizer from virtually any waste stream. While Anaergia was built on the foundations of highly capable and experienced acquisitions, focused investments on innovation and execution capabilities allow us to deliver facilities that divert waste, reduce life cycle costs, create new revenue streams, and maximize renewable energy output.

anessa

anessa’s cloud-based software solutions bring smart analytics into the workflow of anaerobic digestion project developers, biogas consultants, and facility operators.

anessa AD•A provides fast and reliable automated biogas project feasibility studies to assess the viability of potential plants. anessa AD•O helps operators find optimal conditions for existing biogas plants by analyzing every possible feedstock stream and providing detailed instructions on how to mix them. Both tools work together so that biogas developers and operators can know the impact of their decisions before committing, saving time and money.

Antec Biogas AS

Antec is a global energy technology company, headquartered in Oslo, Norway. Its ground-breaking plug-flow biogas technology turns biomass into energy and biofertilizers in record time.

Antec delivers modular AD reactors at scale for industries, farmers and communities anywhere in the world. In addition, Antec builds, owns and operates plants in partnership with biomass owners to accelerate renewable energy production.

SERVICES

Industrial production

- Antec’s plug-flow AD reactors are industrially mass-produced enabling:

- Lower cost

- Shorter ‘time to energy’

- Lower project risk

Industry 4.0 Remote optimization

- Remote monitoring assures limited local operations team with optimal production and high reliability

- Biology advisory

- Asset Performance Management

- Less on-site competence requirement

Biomass partnership

- Antec is a turnkey partner helps you navigate the process from waste to energy to sharing competencies in plug-flow biogas production brings operations and biology competence to run the plant.

- Optimal partner for developing and operating biogas plants

- Technology with high production

- Proven track-record of competence & results

Balmoral Tanks Ltd

Website: https://www.balmoraltanks.com

Balmoral Tanks is a leading design and manufacturing company producing what is believed to be the widest range of tank products from a single European source.

Anaerobic digestion, civil engineering, firefighting, potable/non-potable water, wastewater, desalination and aquaculture are the company’s key markets.

Full technical support including installation, inspection, repair and maintenance is offered.

Balmoral Tanks Ltd

Barrowfield Road

Thurnscoe

Rotherham

South Yorkshire

S63 0EW

tanks-website@balmoral.co.uk

Tel +44 (0)1226 340370

Bioelectrica

Website: https://www.bioelectrica.com/

We are bioelectrics

Leaders in the development of biogas projects from various organic substrates.

Extensive experience in engineering, consulting and project development endorse our track record and team of professionals.

Our goal is to advise our clients to provide them with a comprehensive solution in the development and construction of biogas plants, accompanying them from the development of the idea to their operation.

Bioenergy Association New zealand

Website: Bioenergy – the renewable fuel | Bioenergy Association of New Zealand

The Bioenergy Association represents its members based in New Zealand and Australia. We provide assistance and a wealth of bioenergy information to support members’ business and promote their expertise and capabilities for undertaking activities in New Zealand, Australian and the South Pacific with regards to bioenergy and biofuels related solutions.

Membership

Membership is open to anyone with a commercial interest in bioenergy. Our members include land and forestry owners, wood processors, feedstock suppliers, fuel and energy suppliers, equipment supplies, manufacturers, consultants, contractors, energy researchers, educators, regulators and investors. We advocate to Government on bioenergy related policy, develop best practice Technical Guides for New Zealand and Australia, host workshops and webinars and assist potential investors in bioenergy based solutions to assess technologies, market opportunities and market risks.

BioEnergy Germany

BioEnergy Germany, as part of the BIOENERGY GROUP, combines more than 15 years of experience in the design, manufacturing, operation and financing of biogas plants worldwide, as well as the know-how of biological support of world-wide more than 300 biogas plants. The European headquarter is located in Germany, the South East Asean headquarter is located in Thailand. Here the technology was adapted and developed further to fit the requirements of the SEA and African environment and typical feedstocks. Very common and perfectly known feedstocks are, on example, by products from Palm Oil Mills and starch factories but also other industrial wastes as well as energy crops, animal manure and the organic fraction of MSW. Based on the extensive experiences in biogas technology and the local conditions and challenges of SEA and Africa the technology of BioEnergy Germany guarantees a successful operation.

Biogas Danmark

Website: https://www.biogas.dk/

We work for the entire biogas value chain, which includes everything from the recovery of livestock manure and organic residues from agriculture, households and industry to the production and use of biogas and green manure.

The membership includes biogas plants, suppliers of residual products, technology, service, trade, consulting and financial solutions as well as buyers of biogas and fertilizer from the biogas plants.

Biogas Denmark has approximately 170 members, of which 70 are biogas producers.

![Logo Blu H Energy_rgb[73]](https://www.worldbiogasassociation.org/wp-content/uploads/2023/05/Logo-Blu-H-Energy_rgb73-300x200.png)

Blu H- Energy

Website:Blu-H Energy | Coming Soon

Who we are

We are an Alternative “Green” investment Holding, with an innovative approach to investment opportunities in the new clean energy supply chain, with a strong focus on the Biomethane & Hydrogen sectors.

Our mission

Blu H-Energy aims to “identify and support the most deserving operators and projects developing renewable energies from biomethane and hydrogen, with a multidisciplinary approach to business, technology and finance, thereby promoting the value of their initiatives and creating attractive investment opportunities. At the same time, we promote the development and growth of the sector itself and improved quality of life for the entire planet in line with the principles of sustainable developments that are increasingly emerging and relevant today”.

BTS BIOGAS

Website: https://www.bts-biogas.com/en/

B.T.S. Italia was founded in spring 2008 by engineers, biologists, chemists, agriculturalists and technicians who had devoted themselves to the biogas business for years. We deal with design, installation, construction and operation of biogas plants.

Our numerous experience has contributed to the development of unique technologies in the biogas world – for example the BIOaccelerator or BIOdry – which can increase and optimize the productivity and profitability of our biogas power plants, innovative solutions that allow you to use less biomass, saving up more than 25% of substrates and improving the biological efficiency of more than 80%.

In addition, we offer biological assistance and consulting, we utilize part of our resources to develop appropriate software to computerize the management of the plants and, finally, we have a laboratory, set up in Porto Mantovano (Italy), completely dedicated to biogas world: METANlab. METANlab laboratory is equipped with the most sophisticated equipment, that allows B.T.S. Italia to make all kinds of analysis and, thanks to highly qualified staff, to perform studies until today unthinkable.

Just in 2008 we made 15 biogas power plants with an installed power of approximately 15 MW. These plants are under daily monitoring made by the technical B.T.S. team and by the B.T.S. workers dedicated to the biological assistance; thanks to their own knowledge and experience, their aim is to optimize seeding, harversting, ensilage, drawing and the biological management of the biogas plant.

We are leaders in the fastest growing biogas market with 180 plants built all over Europe. Our strenghts:

-Customer care;

-High professionalism;

-Know how;

-High quality products used;

-Latest technology;

-Full development;

-Constant search of innovations;

-Biological and biochemical monitoring

Cenergy Solutions

Website: ANG Technology | Adsorbent Natural Gas | CNG Conversion Kit (cenergysolutions.com)

Adsorbent natural gas replaces dirty fuels with biogas

Cenergy Solutions has made a game changing breakthrough in Adsorbent Natural Gas (ANG) technology that allows natural/biogas to be stored and transported in large quantities at low pressures which in turn significantly reduces the difficulties and expense of utilizing this abundant and renewable resource. Cenergy Solutions’ low-pressure adsorbent storage now makes it economically feasible to replace dirty fuels around the world with clean natural/biogas.

At oil and gas wellheads, large and small biogas plants, landfills and sewage plants, natural and biogas is vented or burned around the world. This natural resource needs to be captured, stored and utilized to replace the dirty fuels now being used to deliver the energy needed in our homes and businesses. Cenergy Solutions now has the ANG technology to make this switch to a cleaner, safer, cheaper and more abundant energy to help clean our air and use this wasted resource. Large amounts of natural and biogas can be economically transported with ANG technology by truck, rail or ship to meet the world’s energy needs.

Cycle 0 Group Limited

Website: Producing Biomethane From Agri-Food Waste – Cycle0 : Cycle0

At CycleØ, we believe it’s critical to develop smart, achievable and rapid solutions to humankind’s environmental impact. Our mission is to slow the pace of global warming now, by delivering innovative solutions to today’s global environmental challenges.

We focus on capturing methane emissions, the most harmful greenhouse gas. We build, own and operate distributed biomethane plants which are powering the global shift to scalable and sustainable energy for all.

Norwegian Biogas Association / Biogass Norge

Website: https://biogassnorge.no

The Norwegian Biogas Association, Biogass Norge, is an organisation working for companies and organisations in Norway that is part of the biogas market. Biogas has growth potential in Norway both within the transport sector and maritime sector. We represent all of the value chain from waste suppliers, producers, farmers, users and suppliers of production plants. Our members represent both the private and public sector. We consider biogas to be an important part of the future energy mix: It is circular and a smart choice for the climate.

Camlin Energy- HIDDEN

Website: https://www.camlingroup.com/

Camlin operates with the vision of bringing revolutionary products to life for a wide range of industries. We design and manufacture innovative sensing solutions to enhance the performance of our customers’ operations across a range of sectors, including the biogas and biomethane industries.

At Camlin we believe in high quality engineering and design, allowing us to develop market leading products and services. We love creating value for our customers by solving difficult problems.

Clarke Energy

Clarke Energy, a Kohler company, is an multinational specialist in the engineering, installation and maintenance of biogas engine based power plants. Clarke Energy has installed over 1.2GW of biogas-fuelled combined heat and power plants globally. The company’s teams have strong experience of anaerobic digestion technologies and the utilisation of biogas for power generation. Installations include projects in the agricultural, waste, wastewater, dairy and distillery sectors and cover the continents of Europe, Africa, Asia and the Americas

Cranfield University

Website: cranfield.ac.uk

Cranfield is an exclusively postgraduate university, creating leaders in technology and management.

We work closely with business, industry and government across the world. Through our industry partnerships, applied research projects and our executive education and professional development programmes, we work with over 1,500 companies and organisations.

We are focused on the specialist themes of aerospace, defence and security, energy and power, environment and agrifood, manufacturing, transport systems, and water. The Cranfield School of Management is a world leader in management education and research.

Davidson Kempner European Partners, LLP, UK

DMT Environmental Technology

When it comes to biogas upgrading, there is no doubt that DMT Environmental Technology should be your choice. Equipped with almost 30 years of experience we serve our customers and help them with their environmental challenges. Our offices are strategically placed offices in North America, Europa and Asia. DMT has developed a vast amount of biogas treatment technologies. For the key biogas contaminants, DMT can offer one or a combination of technologies to economically manage them. DMT can provide the customer with the best solution for that specific project, either based on CAPEX, OPEX or TCO. Our solutions are the very best the market has to offer. We offer a suite of cost effective solutions that are achieved through our team of engineers and highly motivated employees to help you achieve your goals!

Ecomondo – ITALIAN EXHIBITION GROUP S.p.A.

Ecomondo – Key Energy is a well- established show in Italy and one of the most representative events for the circular economy, green technologies and renewable energies in the Mediterranean area. It takes place in Rimini, Italy, on November 5-8, 2019.

Ecomondo- Key Energy offers an innovative platform with 1,250 exhibiting companies attracting over 80,930 attendees. It has successfully anticipated business changes over time, from waste processing to dialoguing with industry on the development of an economic model based on green technologies. All sectors are efficiently represented, from waste to integrated water cycle, to air, bio-based industry and bioenergies. An entire section is dedicated to biogas, anaerobic digestion and biomethane. The recent Ministry of Economic Development’s decree supports the production of biomethane, enabling its insertion into the national systems’ grids. Industries are now encouraged to invest into biomethane technologies for electrical and heat energy production as well as on advanced biofuel.

EDL Energy

Website: https://enkingint.org

EDL. A world of new energy.

As a leading global producer of sustainable distributed energy, we are dedicated to a world of new energy for our customers, stakeholders and communities. EDL understands, and is prepared for, the complexities associated with a decarbonising energy market.

We own and operate a global portfolio of power stations in Australia, North America and Europe.

Eisele

Website: Eisele

Franz Eisele u. Söhne GmbH & Co. KG

As a manufacturer of pumps and agitators, Franz Eisele und Söhne GmbH and Co. KG can look back on more than 130 years of company history – and an extremely successful one: With our innovative machines and services in the agricultural and biogas sector, we occupy a leading position and are rightly proud to be one of the German market leaders.

Driven by the know-how we have built up over many decades, we as a family company in Lais are continuously developing new solutions for everything to do with pumps and agitators – always taking into account the constantly changing conditions of the market.

Despite a long tradition, our gaze is firmly directed towards the future with a single goal:

To inspire our customers with an Eisele product.

ENGIE

About ENGIE

Our group is a global reference in low-carbon energy and services. In response to the urgency of climate change, our ambition is to become the world leader in the zero carbon transition “as a service” for our customers, in particular global companies and local authorities. We rely on our key activities (renewable energy, gas, services) to offer competitive turnkey solutions.

With our 160,000 employees, our customers, partners and stakeholders, we are a community of Imaginative Builders, committed every day to more harmonious progress.

Turnover in 2018: 60.6 billion Euros. The Group is listed on the Paris and Brussels stock exchanges (ENGI) and is represented in the main financial indices (CAC 40, DJ Euro Stoxx 50, Euronext 100, FTSE Eurotop 100, MSCI Europe) and non-financial indices (DJSI World, DJSI Europe and Euronext Vigeo Eiris – World 120, Eurozone 120, Europe 120, France 20, CAC 40 Governance).

Entsorga

EnviroTaqa

EnviroTaqa L.L.C. is one of the leading environmental services and advisory solutions providers in the environmental research and development, sustainable environmental services, renewable energy andthe waste management industry delivering advanced integrated technological environmental solutions to the private and the public sector institutions.

EnviroTaqa strategy comes from its believes in the scientific researches and the development in the environmental and energy sustainability, all types of waste management which will leads the using of the waste as one of the main sources to provide Egypt and the globe with a safe, secure, affordable and sustainable resources.

Our collaborative approach helps us understand and respond to our clients’ needs, and our team of technical experts prides itself on providing pragmatic, high quality advice to ensure projects proceed efficiently and affordably.

Epower Corporation

Epower Corp. is a renewable energy start-up, with focus on Waste to Energy which comes from Mr. Matsubara’s business activities in renewable energy, developing many small-scale PV plants between 2013 to 2015.

Takuya Matsubara (Mat) is the Representative Director of Epower Corp. with over 30 years of experience in financial services, energy, and investment.

After spending 14 years at Mitsubishi UFJ, and Dresdner Kleinwort in their investment banking units, he joined Enron Corp. to start-up Japan operations. After Enron’s demise, he moved to Cargill Inc. and was responsible for distressed debt investment and structured trade finance. In 2007 he started his own investment activities, mostly in real estate and renewable energy. He was among the first movers when Japan’s PV market emerged after the Great East Japan Earthquake in 2011, and was involved in more than 57MW PV projects.

In 2015, the company started looking into biogas, and the consortium of companies including Epower to date have completed three agricultural biogas power plants. Biogas market in Japan is still in its infancy, and there are only 90 plus plants in operation. The small-scale biogas system engineered by the consortium offers cost-effective solutions to average-sized farmers, hence opens completely new biogas opportunities in Japan. In 2017, their first plant was chosen as the ‘Best International small-scale plant’ by World Biogas Association and ADBA, UK

Future Biogas

Website: UK Biomethane Production & AD Plant Management – Future Biogas

Future Biogas

Future Biogas is a green energy business with farming central to everything we do. Since the company was founded in 2008, we’ve championed the use of sustainably produced energy crops – such as grass, rye and maize – grown on farms local to our anaerobic digestion (AD) plants.

Now one of the largest operators of crop fed AD plants, we operate on a large enough scale to employ our own farming team, all of whom have agricultural backgrounds. They enjoy close working relationships with the 400-plus farmers who grow approximately 400,000 tonnes of a variety of feedstocks for our plants.

We operate plants for JLEN, Aviva, Bio Capital and Aberdeen City Council.

Our plants convert a wide range of feedstocks into clean, renewable energy, through a process of anaerobic digestion which produces biogas. Biogas can either be used to generate green electricity, or upgraded into biomethane and injected in to the UK’s national gas network.

We also provide energy for British Chlorophyll and power for the farming operation at the Holkham Estate in Norfolk.

We have strong links with key trade associations in the industry including the Anaerobic Digestion and Bioresources Association (ADBA), the Maize Grower’s Association (MGA), the National Farmers Union (NFU), the Countryside Alliance, the CLA, European Biogas Association, Renewable Energy Association (REA) and IEA Task 37.

Gas Data Ltd

Specialists in Gas Analysis Techniques

For over 20 years Gas Data Ltd has designed and developed fully engineered gas analysis techniques. Experience that’s at the heart of our range of gas monitoring and analysis equipment.

Business Approach

Our approach is simple: working with the customer, we will make sure we understand all the critical measurements to be made and under what conditions.

- We match or modify our technologies and products to the customer’s requirements.

- We offer and explain the complete solution to our customer.

- We deliver and verify the solution to the customer’s satisfaction.

Fully Accredited

Gas Data is licensed to manufacture ATEX certified gas monitoring equipment as well as MCERTS certified instrumentation (GFM400 series only) and we also have ISO9001 accreditation. All products have to pass through our specialised testing facilities before being delivered to our customers.

Ongoing Support

Purchasing one of our gas monitoring products is just the beginning. We support and maintain our instruments and installations for their entire working lives.

No matter the age of the Gas Data instrument, we will continue to service it!

We have numerous customers in their second decade of operation with Gas Data products. A great testament to the longevity of our instruments when under maintenance contracts and an important reason for our ever-growing Gas Data customer base.

Explore our website for more information on our wide range of gas monitoring and analysis instrumentation or call our technical sales team today on +44(0) 247 630 3311 or via email: sales@gasdata.co.uk.

Gas Networks Ireland

- Our core business remains gas transmission and distribution system operators.

- We will decarbonise the network while enhancing security and assuring delivery.

- Systems Integration is the future and we are committed to working with relevant stakeholders to deliver it.

- We will invest to deliver, transform and realise a clean energy future.

Our 6 Strategic Ambitions

Our strategy sets out how we will continue to operate and maintain our gas network to ensure safe, reliable, affordable and secure supplies while preparing for a future in which networked gas enables an integrated energy system to achieve net zero. We have identified 6 strategic ambitions and they set the foundation for our future success and provide a clear roadmap to deliver on our vision and purpose.

Genia Bioenergy is a company of Genia Global and since the early 2000’s we participate in the development, design, engineering and operation of different kind of facilities such as agro-industrial biogas plants, municipal solid waste treatment plants, sludge valorisation, etc.

So, we have experience in every single phase of the projects:

- Development of business cases for renewable and waste-to-energy projects

- Economic viability studies

- Technical feasibility studies

And also,

- Permits and legalization

- EPCM (Engineering, procurement and construction management)

- Operation & Maintenance

Genia Bioenergy has been part of international project teams in bioenergy and waste treatment projects in Europe, Middle East and Latin America.

GHD

Website: https://www.ghd.com/en-gb/index.aspx

We are committed to solving the world’s biggest challenges in the areas of water, energy and urbanisation.

We are a global professional services company that leads through engineering, construction and architectural expertise. Our forward-looking, innovative approaches connect and sustain communities around the world. Delivering extraordinary social and economic outcomes, we are focused on building lasting relationships with our partners and clients.

Established in 1928, we remain wholly owned by our people. We are 10,000+ diverse and skilled individuals connected by over 200 offices, across five continents – Asia, Australia, Europe, North and South America, and the Pacific region.

Global NRG Advisory Ltd

Website: Biogas Industry | Belfast | Global NRG Advisory Limited

Global NRG Advisory Limited has been set up by biogas industry professionals Chris Negus and Andrew Rice. With a team of industry professionals based in Minneapolis, Tampa, Toronto & London, the team are engaged on projects across the USA, Canada, Indonesia, Germany, Ecuador & Australia as well as 14 other countries.

Utilising a wealth of experience gained through the renewable energy, waste management, investment banking, corporate & commercial banking sectors and environmental law, the team at Global can provide their clients with a bespoke consultancy service. Advising clients from the early stages of development, financial modelling, sourcing of finance, project management and refinancing. In addition they can support market entry in to a variety of offtake agreements to provide additional revenue streams that will support you throughout the journey of your project.

GNR Fortaleza

Website: https://gnrfortaleza.com.br/

Emerged from a partnership between MDC Energia and Marquise Ambiental, GNR Fortaleza is recognized as the largest biomethane plant in the north and northeast of Brazil. Its inauguration in 2017 coincided with the regulation of biomethane by the Brazilian National Agency for Petroleum, Natural Gas and Biofuels (ANP).

Located at the Caucaia landfill in the state of Ceará, which receives daily approximately 5,000 tons of urban solid waste, the plant has the capacity to produce 100,000 m³ of biomethane per day, significantly contributing to the country’s energy transition.

Currently, the project is acclaimed for its pioneering by injecting 100% of its biomethane into the Ceará’s gas distribution network, supplying nearly 20% of the state’s gas consumption.

Greenlane Biogas

Established over 30 years ago we are the world’s largest biogas upgrader and the market leader in water-wash upgrading technology.

Inspired by a commitment to helping waste producers improve their green credentials whist also improving their profitability, we are today the only biogas upgrading company to offer the three main biogas upgrading technologies, providing the widest possible range and most cost effective solutions from the smallest of farm based systems of 100 Nm3/hr to the largest industrial scale applications.

Green Methane

Website: https://www.ghd.com/en-gb/index.aspx

GM has developed a proprietary and proven technology for the upgrading of the Biogas to the Biomethane which core step is the CO2 removal

from the Biogas.

GM take advantage from the specific and synergic background of the partners in the design, construction, operation and maintenance of industrial plants.

GM is qualified to offer:

– Biogas to Biomethane upgrading units on “turnkey” basis;

– After-sales services for a safe and reliable management of the operation, production & maintenance of the upgrading units.

Hitachi Zosen Inova AG

Website: https://www.hz-inova.com/

Hitachi Zosen Inova (HZI) is a global cleantech company operating in energy from waste (EfW) and renewable gas. Our roots are in Switzerland, where we were established in 1933 as “L. von Roll Aktiengesellschaft”, later known as Von Roll Inova. Since 2010 we have been part of the Hitachi Zosen Corporation, one of Japan’s largest industrial and engineering firms and a longstanding partner and licensee of Von Roll Inova. To this day we foster the spirit of a traditional Swiss company combined with the know-how and economic strength of an international group.

We have been building and maintaining plants for almost 90 years. We develop projects with our clients and then draw on our experience as a general engineering, procurement and construction contractor to deliver on their behalf complex turnkey plants and system solutions for thermal and biological EfW recovery, gas upgrading and power to gas. We also offer comprehensive, expert and reliable after-sales services for operators of existing plants. Quality is our greatest asset. Our unconditional endeavours to achieve this quality, together with our long experience and honest commitment, are what we pass on to clients.

The challenge of finding the best possible solutions for our clients, again and again, is what drives us. We work with them closely to find and develop integrated solutions to their individual needs and requirements – solutions based on a blend of proven technologies and passionate innovation that meet the highest quality, efficiency and environmental protection standards. This is why we’re among the market leaders in our field: We love what we do.

Howden

Website: Howden | Chart Industries

Howden provides mission critical air and gas handling products and services, that our customers’ vital processes depend on. We help our customers to increase their environmental and operational efficiencies and to decarbonize their operations. We are advancing a more sustainable future.

For over 160 years, Howden, has been at the forefront of developing engineered solutions for the needs of industrial processes. Today our technology and worldwide engineering expertise and services optimise our customers’ vital processes throughout the world. This is ensured through a strong global network of experts, formed from responsive local service and delivery teams, in more than 100 countries, who are familiar with local requirements and challenges.

The latest chapter of our history is as a Chart Industries company, having been acquired in 2023. The strategic combination of both companies expands our offering of products and solutions across the Nexus of Clean™ – clean power, clean water, clean food and clean industrials. The complementary nature of the equipment and solution portfolios results in a differentiated offering across many industries benefitting customers by enabling a more complete solution to their operational and engineering needs.

HRS Heat Exchangers Ltd

HRS Heat Exchangers operates globally and at the forefront of thermal technology, offering innovative and effective heat transfer products. With a strong focus on managing energy efficiently across the following sectors: Environmental, Food, Pharmaceutical, Industry.

Hudson Valley Vertical Farms, Inc

The Hudson Valley’s heritage as an agrarian Eden is a long and storied one, from Accord’s Saunderskill Farm, which holds the honor of having been in operation since 1680, to our booming pick-your-own offerings. But lately, there’s a different approach to growing that’s gaining a foothold: vertical farming. Instead of spreading seeds and saplings across large stretches of earth, plants cozy up in vertically stacked, layered indoor beds, to better use (and conserve) space and resources.

IES ENERGY GROUP HIDDEN

IES ENERGY GROUP born of the decade experience of IES BIOGAS and starting from the idea that the world’s change cannot be stopped, but only analysed and transformed into new opportunities. Thanks to our dynamism, we enlarge our field of business and technical know-how, expanding or international presence.

IES ENERGY GROUP provides solutions that increase efficiency and optimise energy production from renewable sources. Designing and developing “turnkey”solutions for various sectors and market areas are a daily part of our work. Inside IES ENERGY GROUP there are many divisions including:

IES BIOGAS, since 2008, has built more than 200 “turnkey” biogas plants. This division is specialized in design, construction, management and service of biogas / bio methane plants for the farm sector and food processing industries. IES philosophy is clear: 100% quality on materials, components and finishing. No compromises. The biogas plant is a crucial investment for your farm or agroindustry to overlook details which really prove to be of fundamental importance.

IES WASTE is the division focused on the management and exploitation of the entire waste cycle, starting from the selection and separation stages, to the various treatments and recycling of the main components (paper, cardboard, plastic, aluminium, glass), up to the production of energy from the organic fraction (anaerobic digestion) and secondary solid fuel and, finally, the production of compost. In this sector IES ENERGY GROUP have an important – PATENTEDtechnology – is the “HORIZONTAL DIGESTER” Semi-Dry Fermentation Plug Flow Technology.

Instituto Totum

Website: https://www.institutototum.com.br/

Since 2013, when the Brazilian Renewable Energy Certification Program was launched, electricity consumers in Brazil have had credible instruments to declare their use of

electricity from renewable sources. At that time, the concept of Renewable Energy Certificate (REC) was created, which represents a fact finding that 1 MWh of renewable

energy tracked from a previously registered plant was effectively injected into the electricity grid of Brazil-SIN (National Integrated System).

Through a book and claim system, energy consumers acquire RECs and take possession of the renewable share of energy injected into the grid. A centralized platform for the

emission and control of RECs guarantees the physical existence of the energy generated and the proven source of renewable energy, in addition to the lack of a double

beneficiary.

I-REC Standard

Website: https://www.irecstandard.org/

Facilitating standardized REC schemes around the world

The International REC Standard Foundation (I-REC Standard) is a non-profit organization that provides a robust standard for developing attribute tracking systems. The I-REC Standard is acknowledged by major reporting frameworks such as the Greenhouse Gas Protocol (GHGP), CDP, and RE100 as a reliable backbone for credible and auditable tracking instruments. It ensures the highest quality systems and adherence to best practices designed to avoid double counting, double certificate issuance, and double attribute claims.

The I-REC Standard’s International Attribute Tracking Standard ensures that market facilitators adhere to best practices and good governance principles for the tracking instrument and the associated markets they manage. In this way, the I-REC Standard represents a globally recognized standard, which is often referred to as I-REC, that can be implemented for a myriad of products both within and beyond the energy sector that can benefit from harmonization, recognition, market support, and independent oversight. Recognized Issuers, stakeholders, and government bodies can consistently rely on the I-REC Standard and its associated Product Codes while implementing and running robust attribute tracking systems.

The I-REC Standard is committed to ensuring unbiased access to product information and allowing end-users to confidently procure products whose origins are well documented and clearly accounted for, thus empowering renewable energy consumption choices around the world and supporting claims of sustainability.

Malaby Biogas

Bore Hill Farm Biodigester is Phase 1 of a 3 phase multi-use site which is acting as a model scheme for sustainable development and innovation. It combines commercial employment units (Phase 2A), integrated R&D and Training centre (Phase 2B) and residential housing development (Phase 3).

Bore Hill Farm Biodigester is at the vanguard of sustainability best practice being the first commercial biogas plant in Wiltshire and the only plant in the UK to be designed for close integration with other mixed-use land development.

The AD plant has been operational for over six years and is currently operating at twice its designed output with 65% increase in inputs using the same process space. Innovation, deliverability and excellence are core philosophies and a strong ethos of collaboration is evident in all operations. Creating and delivering a new paradigm in development, waste management and energy generation and use is the main driver behind the company’s work and Bore Hill Farm Biodigester is evidence of this.

Malaby Biogas ran a long-term local food waste collection trial called Direct to AD. This innovative service was established to demonstrate the advantages of local food waste collection and processing in reducing contamination levels. It encouraged local businesses to manage their waste more efficiently and dispose of it responsibly. During the trial a study was carried out on the use of paper bag liners as an alternative to plastics used in commercial operations across the UK.

Malaby Biogas has won national awards for innovation in AD and is an active member of ADBA, REA, CIWM, AEA Task 37 and ADNet.

MDC

Home

Founded in 2006 and operating throughout the country, MDC invests in energy assets with a presence throughout the chain of natural gas, biomethane, renewable electricity and steam through biomass, in addition to environmental attributes such as carbon credits and biomethane traceability certificates (GAS-REC).

The Group’s work ranges from production and processing to distribution and marketing to the end consumer. In this way, MDC consolidates its integrated and innovative operating model. Through the operations of the subsidiaries Energias Renováveis do Brasil (ERB), Companhia Distribuidora Gás Natural (CDGN) and Ecometano, our Group offers a broad portfolio of long-term sustainable energy solutions to corporate clients.

Our business is developed synergistically and based on the tripod of sustainability – economic, socio-environmental and governance. Through the integration between the group’s companies, the company is able to offer solutions with competitive prices for all customers, in addition to mitigating the risks involved.

Environmental commitment is inherent to the business developed in our Company. Currently, about 85% of the energy delivered to customers comes from sustainable or renewable sources. Thus, our core activity is aligned with the transition to a low-carbon economy experienced by the world and accelerated by the ESG (Environmental, Social and Governance) agenda.

All our activities are focused on customer service and the concern to offer a sustainable energy drink combined with the company’s purpose.

To this end, the company invests in reliability, ensuring high quality standards, compliance with the strictest safety standards, continuity of services and monitoring of operations in a center that manages the entire chain online 24 hours a day, 7 days a week.

Montello

Montello S.p.A. is located in an industrial area of approximately 450,000 square meters, of which 120,000 are covered.

Up until the end of 1995 it was a steel industry for the production of reinforcing steel bars.

In 1996, after repeated crises in the national steel industry, the decision was to close the steel industry company (Brown Economy), converting the plant into recovery and recycling of packaging waste in post-consumer plastic and organic waste from separate waste collection (Green Economy) which, at that time, began to become popular in Lombardy.

And that is how the concept of waste/resource towards a Circular Economy begins.

With this production reconversion, today the company Montello S.p.A. employs 650 people (compared to the 320 who were employed at the time of the closure of the steel industry company).

At the moment, the factory in Montello (BG) recycles 200,000 tons a year of post-consumer plastic packaging from which new products are obtained, and 600,000 tons a year of OFMSW Organic Fraction deriving from the separate collection from which biogas is obtained, used to produce both electric and thermal energy and biomethane, at the same time recovering CO2 carbon dioxide for industrial technical use and producing a high quality organic fertilizer.

The company has obtained, over the years, ISO 9001,

ISO 14001, ISO 18001 and ISO 50001 certifications. From the month of October 2017 the company has also obtained certification in sustainability of biomethane produced for automotive use.

Montello S.p.A. is an example of excellence, both nationally and internationally, for an integrated system and applied advanced technology.

Nature Energy

Adding value to energy

Supplier of energy to all of Denmark

Nature Energy has been on board ever since the inception of natural gas in 1979.

Each year, we deliver more than 300 million m3 of gas to over 55,000 domestic customers and businesses throughout Denmark.

Leading the way in green transition

Nature Energy is a biogas pioneer. We see it as our duty to be proactive in Denmark’s transition to green energy, and we consider biogas to be the third pillar in this project, combined with solar and wind power.

With ten plants, we are Denmark’s leading producer of biogas, each year converting over 1,000,000 tonnes of waste, etc., into biogas – enough to heat more than 30,000 households with sustainable energy.

We also supply biogas for cars from a number of filling stations. And we will continue to develop biogas production in cooperation with our partners in sustainable management of waste from households, agriculture and industry.

Normec Group

Website: https://normecgroup.com/

The number one in testing, inspecting, and certification

Normec is a leading organisation in the Testing, Inspection, Certification, Compliance (TICC) industry. Our areas of expertise range from water, air and soil quality to fire safety, food safety and management systems.stations. And we will continue to develop biogas production in cooperation with our partners in sustainable management of waste from households, agriculture and industry.

Window of Opportunities

At Normec, first and foremost, we assist our clients with Testing, Inspection, Certification and Compliance, or TICC for short.

Our knowledge and experience in these areas and the latest technology we apply to them take our clients a crucial step forward every day. Moreover, we help quality managers for government agencies and companies with something even more valuable. We help them with opportunities. Because we are enterprising, we look for additional opportunities. We go the extra mile, or as we are fond of saying at Normec, we seek a window of opportunities. And that is reflected in our logo.

Safely pioneering

Normec tests, inspects and certifies so that organisations can innovate safely, quickly, efficiently and cost-effectively. Thanks to our team of seasoned experts, we have rapidly gained a reputation as the top specialist in the field of quality and safety.

Our mission remains the same as that of the small organisation that saw the light of day in 2015: we want to support innovation in an ever-changing world. That way, our clients can safely continue trailblazing the way forward. Together with our clients, we see or create opportunities!

Today, we have over 4,000 motivated employees working to improve our clients’ organisations every day. We are the proud employer of professionals with years of experience in and knowledge of the industry in which they operate. Clients regard the contact with every inspection team as pleasant. Personal. Committed. We deep-dive into an organisation. Comprehensive test reports, fast but thorough and well-automated certification procedures: this is the standard as far as we are concerned. Because we also provide organisations with advice they can rely on, we set a new standard with the client.

Nortegas Renovables

Website: https://www.nortegas.es/

The NORTEGAS Group is developing new business around renewable gases (hydrogen, biomethane, etc.) and its role in the sustainable energy transition.

This initiative reinforces Nortegas’ strong commitment to the energy transition, the digital agenda and the circular economy, by promoting the widespread use of clean and sustainable fuels, as well as initiatives and activities around gases of renewable origin.

In this context, NORTEGAS Renovables is born, the brand under which we develop all the NORTEGAS Group’s projects related to renewable gases such as biomethane, and with which we aim to promote a more sustainable future in order to achieve our main objective: the decarbonization of the economy.

Throughout the life of the project, from the initial phase to the commissioning of a biomethane production plant, NORTEGAS offers solutions that cover the entire value chain of the project, starting with the initial consultation and going through the different phases: promotion, partner search, financing, execution and operation, including biomethane marketing agreements.

At NORTEGAS Renovables, we want to do things differently:

- We think globally, creating a platform of projects focused on sustainable infrastructure development and promotion.

- We act locally, producing indigenous renewable energy with a guarantee of origin that promotes sustainable management and improving the circular economy.

- We think in the future, with a long-term vision, because we are a company that remains and a key element in the energy transition.

- We act in the present, creating and promoting sustainable, quality employment, working on smart infrastructures, with interest for new generations.

- Integral projects: participation in the operation and maintenance of the plants throughout the entire process, thus guaranteeing a safe and stable injection of biomethane into the grid.

Decarbonizing the Transportation Sector

As the world looks for innovative solutions to reduce the growing threat of global emissions and related health issues, it is clear that decarbonizing the transportation sector is a must. At the same time, waste streams generated by agriculture, manufacturing, and growing populations are creating new challenges around the world which also must be addressed.

Enter Oberon Fuels. We develop a range of ultra low-carbon or carbon-negative fuels that are practical, economical, and sustainable alternatives to today’s fossil fuels that can be produced from a variety of waste streams. Our approach reduces emissions while creating new economic opportunities for our partners.

Oberon’s renewable Dimethyl Ether (rDME) fuel is a cost-effective, low-carbon, zero-soot alternative to petroleum diesel. In addition, rDME is also a cost-effective carrier for hydrogen, making it easy to deliver this renewable fuel for the growing hydrogen fuel cell vehicle industry.

Additionally, when blended with propane, rDME can significantly reduce this commonly-used, clean-burning fuel’s carbon intensity. Taken together, Oberon can provide the US and global transportation sectors with practical and affordable pathways to zero-emission mobility.

We are proud to be part of a growing coalition of forward-looking vehicle manufacturers, infrastructure developers, and fuel providers who are 100% committed to making rDME a key to the long-term sustainability of our local, national, and global economies.

Octaform

Website: https://www.octaform.com/applications/biogas/

BUILD A BETTER BIOGAS TANK

The biogas produced by an anaerobic digestion plant is composed of combustible gases methane (50-75%), carbon dioxide (25-50%), water (H2O), nitrogen (N2), oxygen (O2 ), hydrogen sulfide (H2S), ammonia (NH3), and trace elements (organo-halogenated, siloxanes, etc.). H2S, CO2, and water make the biogas very corrosive.

Whether you’re fighting greenhouse gasses or the rising cost of energy, let Octaform help you build an anaerobic digester that will last. Octaform’s built-in PVC finish offers the best possible defense against the highly corrosive digestion process that will test the limits of any tank technology.

Oman Environmental Services Holding Co. (be’ah)

Oman Environmental Services Holding Company S.A.O.C “be’ah” was established in 2007. In 2009, Royal Decree No. 46/2009, granted be’ah the mandate and the legal status as the entity responsible for solid waste management in the Sultanate of Oman.

be’ah strives towards a vision to “conserve the environment of a beautiful Oman for future generations”. be’ah’s main objectives are to control environmental damage incurred during traditional waste dumping processes; structure the waste sector and its related services in a sustainable manner; develop the industry; and support the economy.

Within this umbrella, be’ah works on moving towards sustainable waste management practices as per the international standards by establishing the required infrastructure, restructure the municipal waste collection services and improve public awareness of waste management.

OMEX Environmental Ltd

OMEX Environmental Ltd are based in the UK and operate worldwide, providing biological and nutrient additives for the energy, water and transport sectors.

OMEX offer a complete nutritional package of essential supplements including bioavailable liquid trace element solutions, enzymes, micronutrient blends to boost the availability of essential trace elements and a range of iron powders all used in the anaerobic process to help improve the bacterial performance in the digestate and increase the methane content of biogas production. This helps commercial operators to run their plants at optimum levels, maximising their revenue streams and return on investment through increased profits.

The OMEX support service includes a nutrient profiling service in their fully-equipped laboratory with analysis of plant influent, effluent and biomass, through which a nutrient solution will be recommended. Dependent on the individual requirements of the plant and operations, a tailor-made micronutrient solution can be produced. This support service also includes onsite visits, consistent and effective aftercare.

As well as specialising in trace element additives, OMEX Environmental Ltd also manufacture and supply a complete range of wastewater treatment solutions for anaerobic and aerobic systems as well as de-icers and concrete ad-mixtures.

QUBE Renewables Ltd

Website: https://www.quberenewables.co.uk

The first QUBE digester was designed in response to a request from the UK’s Ministry of Defence (MOD) to deal with food and sewage waste, and provide energy, on their forward operating bases. The digestion technology had to be robust, easily transportable, and simple to operate and service.

Our first QUBE digesters were built on these principles, and have since completed thousands of hours of continuous waste processing and biogas production.

Collectively, the team at QUBE Renewables have many years’ experience developing commercial waste and energy projects.

We design and build in the UK, but work with collaborators across the world to deliver projects.

Renesco

RENESCO Enerji Sanayi ve Ticaret A.Ş; is a project undertaking, consulting and energy company that develops technology and produces energy efficiency solutions that lead to change.

The sustainability of the sectors depends on the energy supply chain. For this reason, we are in favour of cleaner environment and recyclable energy consumption with our company profile aiming at energy efficiency and efficient use of resources. Recently, with R&D and increasing investments, each waste has started to be seen as an energy value and in this context, recycling these energy elements that we have discarded as the final product and recycling them to the economy and the environment as raw materials, new products or electricity has become our primary goal.

Renergon International AG

Website: https://www.renergon-biogas.com/en/

RENERGON International AG is a dynamic, innovative and globally active company with forward-looking solutions and technologies based on biogas production from biogenic waste. With headquarters in Lengwil, Switzerland and a subsidiary in Berlin, Germany, and a worldwide network of partners, we guarantee success as a globally active Greentech champion with patented technology – from an economic and ecological point of view.

We stand for sustainability, local added value and closed material cycles (circular economy), and focus on a clean and liveable environment through renewable energies and fuels as well as healthy soils through compost, fertilizer, and biochar. We stand for:

INNOVATIVE BIOGAS TECHNOLOGY & SOLUTIONS

COMPLETE RECYCLING OF WASTE

EFFICIENT ENERGY PRODUCTION FROM ORGANIC WASTE

RETURN OF NUTRIENTS TO THE NATURAL CYCLE

RESPONSIBILITY FOR THE ENVIRONMENT & FUTURE GENERATIONS

revis bioenergy GmbH

Website: revis-bioenergy.de

We are the specialist when it comes to the production and offtake of biomethane and other green fuels and gases from waste and residues / manure and slurry. As a medium-sized family business based in Münster, we can draw on 10 years of construction and operating experience of biogas projects throughout Germany. With the planned large-scale plant “nordfuel” in Cloppenburg and the LNG liquefaction plant in Dülmen, we are making a major contribution to the decarbonization of the transport sector. In addition to our own projects, we support existing operators in the future-proof conversion of their biogas plants. This includes the project planning, construction as well as the operation of the plants including the substrate management and the guaranteed purchase of the generated products. Whether biomethane, green gases or green fertilizer products – we as revis want to make our contribution to a successful energy and transport transition.

Sebigas Renewable Energy

Website: https://www.sebigas.it/en/

Since 2008 SEBIGAS designs, constructs and manages biogas plants world wide. Supported by the industrial experience and capability of the TICA Group, SEBIGAS can offer a solid expertise and customized solutions in the biogas sector, with a portfolio of over 80 biogas plants located all over the world, with units from 100 kW to 3 MW. SEBIGAS can offer tailored plants that satisfy the clients’ needs, exploit the potential of the substrate and guarantee optimal and long lasting performances. SEBIGAS portfolio today boasts a track record of over 8700 hours/year of operation at the maximum power.

With headquarters in Italy and thanks to the TICA Group worldwide presence SEBIGAS is able to operate in the major worldwide markets where its solutions are requested.

Specialties: Biogas, Biomass, Organic Municipal Waste, Anaerobic Digestion, Food waste, House waste, Turn key plant, by-products, biomethane, Renewables, and Agricolture

School Of Impact

Website: https://school-of-impact.com/

The School of Positive Impact, Innovation and Sustainable Development Management

A school designed as an accelerator at the service of your professional success in the management of sustainable development and positive impact.

An innovative program, with a major asset: easy access to quality work-study thanks to our network of expert partner companies.

An inspirational, theoretical and highly committed training in action: contacts with decision-makers, startups, large expert groups, public actors, NGOs and CSR platforms, with the sole objective of your professional success in a sector of the future

SG Tech

Founded in 2015, Sustainable Green Technologies (SGTech) was born out of the desire to create a more sustainable world.

Specifically, SGTech has aimed to address environmental issues resulting from improper waste management in the livestock industry.

Through years of Research and Development, SGTech has developed innovations in nutrient recovery, integrated biogas solutions, and water recycling.

We are now in the process of designing and building custom-made treatment plants that best suit each farms’ specific needs.

SGTech’s patented Integrated Ecosystem Solution (IES) is an Anaerobic Digestion (AD) technology specifically designed for the treatment of livestock waste – the technology produces enriched biogas and simultaneously removes and recovers nutrients from the waste stream.

The result is an end-to-end solution that improves each area of sustainable agriculture – cleaner energy, cleaner water, and cleaner soil.

Shell

Website: Shell Global

Shell is an international energy company with expertise in the exploration, production, refining and marketing of oil and natural gas, and the manufacturing and marketing of chemicals.

We use advanced technologies and take an innovative approach to help build a sustainable energy future. We also invest in power, including from low-carbon sources such as wind and solar; and new fuels for transport, such as advanced biofuels and hydrogen.

SHV Energy

SHV Energy Group is an off-grid LPG distributor serving over 30 million customers around the globe with decentralised, clean, safe and efficient energy. SHV Energy customers rely on its products for a wide variety of applications including domestic, industrial and transport solutions. SHV Energy strategy for sustainable development over the next 20 years is to ensure that the source and supply of its clean, safe and efficient gas products becomes increasingly renewable, bio-based and lowest carbon. SHV Energy is proud to pioneer bioLPG since 2018.

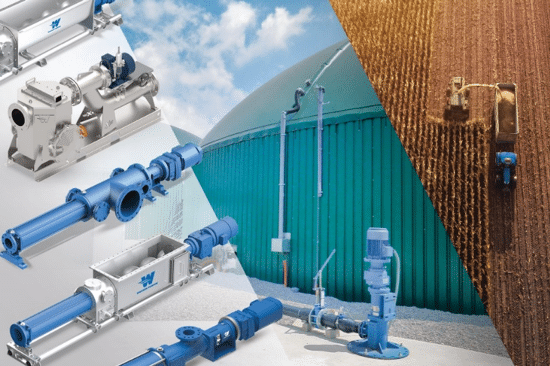

Strong partner for biogas plants and digestion.

As a specialist in the design, manufacture and assembly of high-quality stainless steel products such as tanks, pumps, agitators and separators we are the competent partner for the biogas industry. Our broad range of products is successfully used in agriculture and industry all over the world. More than 40 years of experience show that our products are reliable. With our products we optimize gas yields and reduce costs. Strong components are required.

Stallkamp Separator – A high level of performance even at a high level of dry matter

Stallkamp Agitator – The fluid flow accelerator

Stallkamp Pump – Our Power Packs

Stallkamp Stainless Steel Tank – Quality. Persistence. Safety.

website: www.stallkamp.de

SUEZ – Water Technologies & Solutions

As a strategic business partner, SUEZ offers the most comprehensive set of chemical and equipment solutions and services available, helping our customers manage and optimize their water resources and process challenges across industries and municipalities.

Suma Rührtechnik GmbH

Website: https://www.suma.de/

Welcome to SUMA, your provider for agitators, mixers and pumps specifically designed for biogas plants and liquid manure tanks or lagoons. We’ve been delivering agitation and pumping solutions for over 65 years in the biogas, manure and waste water industry. Our knowledge and exclusive technology combined with our field-related expertise makes SUMA able to optimize and deliver custom solutions for your business. With SUMA, your results will be efficient liquid manure management, reliable biogas yields and optimized industrial processes.

SustainRNG

Website: https://sustainrng.com/

SustainRNG℠ is an agile, entrepreneurial developer of renewable natural gas (RNG) projects originally formed to deploy proprietary methane capture technology for dairy manure projects as small as 1500 wet cow equivalents (WCEs). SustainRNG is rapidly maturing into a technology leader in the RNG industry by investing in a portfolio of intellectual property that complements our core anaerobic digestion business, while providing farmers with agronomic, economic, and environmental solutions that enable sustainable growth for the next generation.

Today, our project portfolio, presently centered in the southeastern US and expanding nationwide, consists of on-farm dairy digester projects and natural gas pipeline interconnection projects. These interconnection projects help de-risk our business by ensuring a path to market for our RNG while diversifying our business into a downstream, synergistic activity. We continuously look to expand our project pipeline, including making investments in opportunities adjacent to our core business that reduce risk, improve profitability and strengthen competitiveness.

Duke Energy is a significant and active investor in the Company and has provided us with the ability to execute projects efficiently and rapidly. We are adding additional investors to our platform to ensure we have the financial strength to realize our bold vision to be the industry’s leading vertically integrated owner/operator of RNG projects.

Tan Delta Systems

Website: https://www.tandeltasystems.com/

Tan Delta Systems PLC is a global leader in oil condition monitoring technology for all types of industrial equipment, including that used in the bioenergy sector.

Tan Delta’s unique technology uses advanced real-time oil analysis which enables a dramatic reduction in your equipment operating costs. Adopted by some of the world’s largest equipment operators, our systems are proven to reduce maintenance costs, reduce oil consumption, reduce break downs and reduce carbon footprint. Our systems are easily fitted to any equipment using any oil in any application. Our unique FSH technology analyses oil at a molecular level in real-time, detecting all and any changes caused by either contamination or wear. Combined with Tan Delta analytics this enables accurate identification and prediction of optimal maintenance based on equipment need instead of time-based scheduling. This results in reduced maintenance, as intervals are extended, with a safety overwatch as any unexpected issues, are immediately detected and an alert provided.

Tecno Project Industriale

Website: https://www.tecnoproject.com/web/tecnoproject

Tecno Project Industriale is an Italian company which provides solutions for the Industrial Gas Markets – from the Beverage Industry to any other Gas Application.

In the past 30 years, TPI has been the leader in many of the improvements to the existing technology that have now become the standards in the CO2 industry.

These developments, together with TPI’s dedication to continuous improvement, ensure each application is applied with the latest technology.

TPI’s plants incorporate innovative solutions which meet and often exceed industry requirements for the treatment and purification of CO2, Compressed Air, Nitrogen, Hydrogen, Nitrous Oxide and any other primary gas used in modern day industries.

Compression, purification, de-oxidation, production and recovery of Industrial Gases are the fields where TPI applies its knowhow and technology.

TPI’s plants are always turn-key supplies: commissioning and start up are included all around the world.

Moreover a just-in-time service for Spare Parts and Aftersales Service ensures the proper operation of TPI equipment wherever installed.

Pre-assembled units can be tested and proven in TPI’s factory in simulated on-site conditions.

The main factors that make Tecno Project so successful for the most demanding customer requirements and markets include TPI’s design strategy driven by: Consumption Optimization, Rational Automation, Reliability of Control, Systems, Repeatability and Safe Operation.

A review of customers’ site conditions always facilitates the installation of TPI’s units, particularly when they have to be placed close to existing production equipment.

Since 2011, Tecno Project Industriale has offered a comprehensive range of systems to cover each stage of the Biogas treatment process: Biogas Upgrading plants with membrane or selective solvents and a complete range of accessories precisely designed to cover the end user’s needs.

In 2013 Pentatec became the Gas Analysis Division of Tecno Project Industriale for the supply of gas analysis instruments and systems for quality control of gases in the Beverage and Industrial Gas industries.

In 2014 Tecno Project Industriale became part of the SIAD Group which further enhanced its total capability for producing world-class, tailor made solutions in the Industrial Gas Markets.

Technical Bioenergy Crete

Technical Bioenergy Crete (TBK) is part of the SYCHEM Group of Companies www.sychem.gr

TBK owns a Biogas Plant for Electricity Production with installed capacity 500 Kw upgradable to 2 MW that is located in a total area of 15 acres at the Industrial Area of Heraklion, Crete.

The biogas plant was entirely designed and constructed by SYCHEM Group, applying cutting-edge technology at the most critical points of production process such as the collection and management of the incoming organic waste, the deodorization system, the reuse of produced heat energy and the innovative system for the biological treatment of the digestate effluent.

The Plant aims to become a European pattern for the management and utilization of organic waste from slaughter houses, livestock and poultry factories, expired food etc. With an automatic process for collection and separation/ unpacking, odorless, the utilization of the total produced heat energy but also with the innovative wastewater treatment system, biogas plant is able to offer a pioneer, reliable, environmental friendly and cost efficient solution of managing difficult to treat organic wastes, integrated in an urban environment.

The National Institute of Agricultural Technology (INTA)

The National Institute of Agricultural Technology (INTA) is a decentralized state agency with operational and financial autarchy, under the Ministry of Agroindustry in Argentina. Its efforts are oriented to innovation as a motor of development and integrates capacities to foster interinstitutional cooperation, generate knowledge and technologies and put them at the service of the sector through its extension, information and communication systems.

The institution has a presence in the five ecoregions of Argentina (Northwest, Northeast, Cuyo, Pampeana and Patagonia), through a structure that includes: a central headquarters, 15 regional centers , 52 experimental stations, 6 research centers and 22 institutes Of research , and more than 350 Extension Units. The result of INTA’s work allows the country to achieve greater potential and opportunities to access regional and international markets with products and services with high added value.

TotalEnergies

TotalEnergies and Biomethane

Biomethane is a renewable gas that has a key role to play in the energy transition. TotalEnergies is the segment leader in France, with close to 500 GWh of production capacity, and aims to become a major player in biomethane internationally by partnering with market leaders in other geographies, such as Clean Energy in the United States and Adani in India. The Company is active across the entire biomethane value chain, from project development to marketing of biomethane and its by-products (biofertilizers, bioCO2). It aims to produce 2 TWh of biomethane per year by 2025 – equivalent to the average annual consumption of 670,000 French consumers, and a reduction in CO2 emissions of 400,000 tonnes.

website : https://totalenergies.com/

Tratolixo

The company TRATOLIXO – Solid Waste Management, has been in business since 1989 and is responsible for integrated management of Municipal Solid Waste (MSW) produced in the system of AMTRES (Municipal Association of Cascais, Mafra, Sintra and Oeiras), which holds the entire share capital of the company. Covering a geographical area of 753 km2, it provides service to a population of 840.000 inhabitants, which represents approximately 8% of the national population and it’s one of largest MSWM in Portugal. This population has one of the highest purchasing capacity in the country as measured by GDP per capita. TRATOLIXO is responsible for the treatment, disposal, recovery and recycling of municipal solid waste (MSW), taking into account the principles of sustainability and implementation of legislation and national and international recommendations ruling the waste sector. With over 25 years of experience, the company has learned to value more and better the waste received from their municipalities, offering dedicated and specialized infrastructures to the treatment of MSW.

The company has several infrastructures for waste management: Trajouce’s Ecopark, Abrunheira’s Ecopark and Ericeira’s Ecocenter.

TRATOLIXO is certified according to NP EN ISO 9001:2008 – Quality Management System – and OHSAS 18001/NP 4397:2008 – Occupational Health and Safety Management System at Work – and since 2013, in Abrunheira´s Anaerobic Digestion Plant (ADP) is also certified according to NP EN ISO 14001:2004 – Environmental Management System.

Varo Energy

Website: https://www.varoenergy.com/

VARO was created in 2012 and is a leading European energy company that manufactures, stores and distributes conventional fuels and sustainable energies and services.

OUR PURPOSE

We exist to accelerate the transition to a world of reliable, accessible, sustainable energy.

OUR VISION

We will be the energy transition partner of choice.

We are recognised as the agile, progressive partner in the energy value chain by customers, partners and governments.

OUR MISSION

We build, we partner, we empower to deliver energy solutions for our customers and the world.

WANGEN PUMPEN

Europe´s No 1: Reliable pumps for anaerobic digestion

Powerful and reliable pumping solutions for anaerobic digestion plants. WANGEN PUMPEN offers a multitude of pump models for various tasks at biogas plants:

- Feeding of Solid solids in fermenter: In the WANGEN BIO-MIX hopper pump, grass silage is pre-mixed with digestate or slurry and pumped into the fermenters

- Digestate/Slurry pumping: the conveying of viscous digestate between fermenters

- Separator feeding: WANGEN pumps take on special operations in biogas plants, such as e.g. the loading of the separators used to separate the solid and liquid biomass material

German engineering, used worldwide. The WANGEN pump company has been producing progressing cavity pumps for over 50 years! Over 50.000 pumps have been supplied to the global Anaerobic Digestion and Agriculture industry. Leading plants worldwide are already successfully operating with WANGEN´s innovative pumping technology. Key to the success of WANGEN pumps is the very robust pump design and high stability Cardan joint and our own design of heavy duty mechanical seal specifically engineered for extremely arduous applications.

WANGEN PUMPEN. This is us. Our world in 3 minutes.

WANGEN BIO-MIX pump for anaerobic digestion substrates

Powerful and reliable: WANGEN´s pumping technology for anaerobic digestion plants.

Zhongyi FRP Co., Ltd

Website: Zhongyi FRP Co., Ltd (zyfrpgroup.com)